Machine Tool and General Production Equipment

Fitting, repair and technical assistance for CNC or conventional Machine tool, general production equipment and production lines.

- Comprehensive repair: mechanical, electrical, electronic, transmission, sealing, lubrication, hydraulic pneumatics.

- Repair of orthogonal, twist, straight milling heads, direct mandrels, electro-mandrels, etc...

- Repair of lathe heads, grinders, special machines, etc…

- In-situ tool holder cones grinding.

- Standardize or custom-made spare parts, mechanical-transmission-sealing-electronic, repair and/or exchange.

- Assembly, Installation and commissioning of new machines.

- Transfers or redistribution in plant.

- Assistance to the of manufacturer-representatives’ SAT in the area for technical support, commissioning’s and corrective actions.

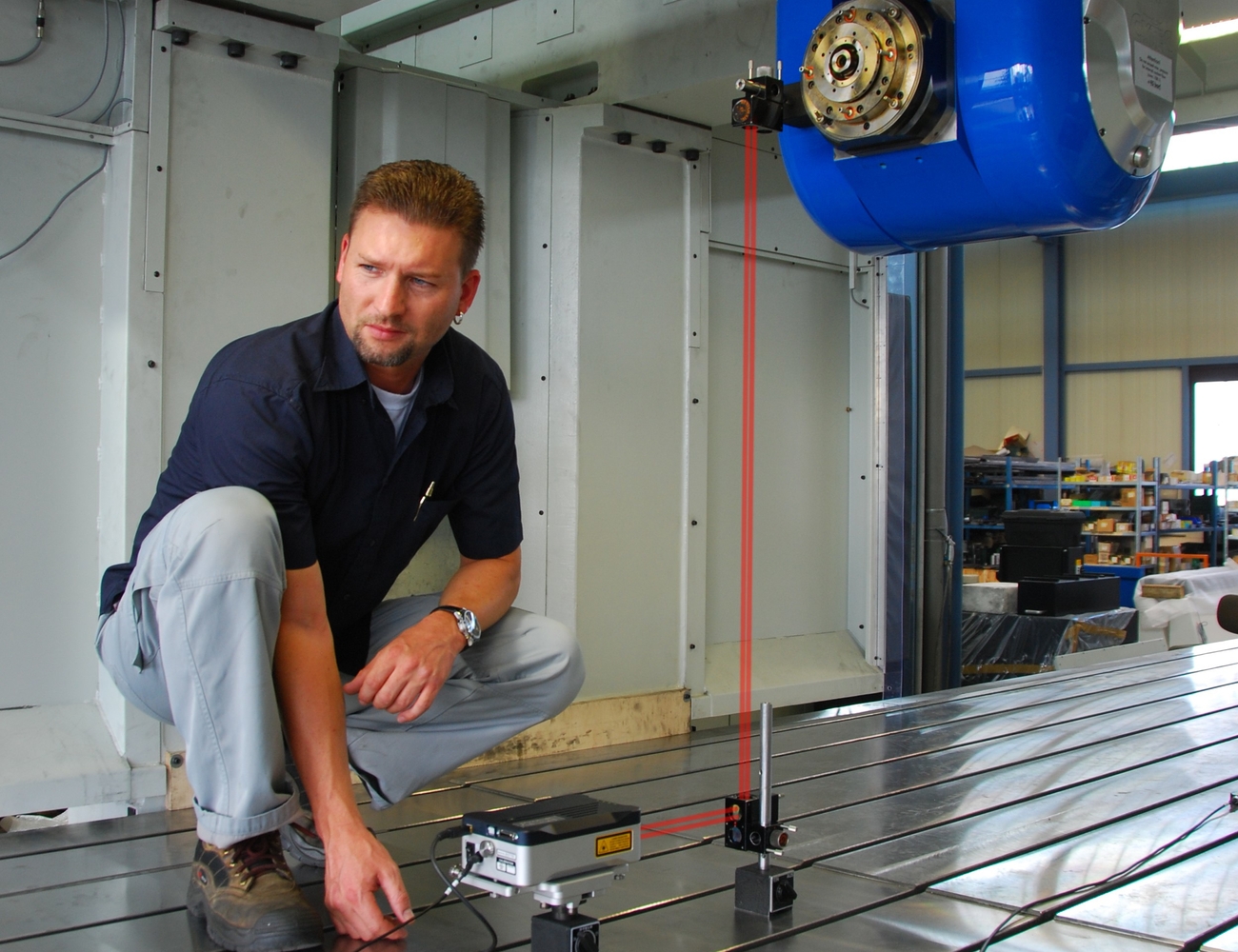

- Machine geometry, levelling and verification.

- XL80 Renishaw and Ball Bar QC20 Laser in property for calibration and verification of machine’s position and straightness.

Click on the image to enlarge